Analysis of the internal structure of the rectifier bridge module

2021/6/25

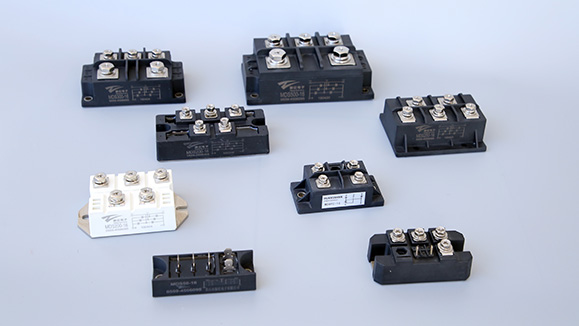

As a power component, the rectifier bridge module is widely used in various power equipment.

Its internal is mainly composed of four diodes to realize the conversion of the input AC voltage into the output DC voltage.

In each working cycle of the rectifier bridge module, only two diodes work at the same time, and the unidirectional conduction function of the diodes converts the alternating current into a unidirectional direct current pulsating voltage.

Anatomy of the commonly used low-power rectifier bridges will find that the internal structure shows that the full-wave rectifier bridge adopts a plastic package structure (most low-power rectifier bridges use this package form). The four main heating components in the bridge—diodes are divided into two groups and placed on the copper plate of the DC output pins. There are two connecting copper plates between the DC output pin copper plates, and they are respectively connected to the input pins (AC input wires) to form a full-wave rectifier bridge with four external connection pins that we see on the outside.

Since the general rectifier bridge module adopts a plastic packaging structure, the surroundings of the above-mentioned diodes, pin copper plates, connecting copper plates and connecting wires are filled with epoxy resin as an insulating and thermally conductive skeleton filling material. However, the thermal conductivity of epoxy resin is relatively low (usually 0.35℃W/m, higher is 2.5℃W/m), so the junction-case thermal resistance of the rectifier bridge is generally relatively large (usually 1.0~ 10℃/W). Under normal circumstances, in the relevant parameter table of the component, the manufacturer will provide the junction-ambient thermal resistance (Rja) of the device under natural cooling and when the component comes with a heat sink, the device is cooled by the heat sink. The junction-case thermal resistance (Rjc).

Huangshan City Zhen Yi Electronics Co.,Ltd. All rights reserved 皖ICP备12019564号 Disclaimer